top of page

SMART WAREHOUSING

Predictive Maintenance Planning

Our facilities are equipped with advanced systems that enable predictive maintenance, minimizing downtime and ensuring operational reliability. Safety is reinforced through VESDA (Very Early Smoke Detection Alerts), providing proactive fire prevention measures. In addition, a network of smart sensors and data loggers continuously tracks environmental parameters, while comprehensive facility metrics offer actionable insights to optimize performance and maintain the highest standards of safety and efficiency.

Remote Monitoring and Visitbility

We integrate advanced monitoring systems that provide precise time–temperature mapping, ensuring complete control over storage conditions. Our facilities also track real-time energy consumption, enabling efficiency optimization and sustainable operations. In addition, proactive security alerts safeguard both products and infrastructure, reinforcing reliability and peace of mind across the supply chain.

Digital Collaboration

We ensure complete transparency and control through daily reports that provide clear insights into operations. Our robust support systems guarantee seamless functioning across all processes, while our cloud-based ERP platform enables real-time data access, streamlined workflows, and efficient decision-making from anywhere.

Control Tower

Our centralized control tower oversees all operations, ensuring end-to-end coordination and efficiency. With complete visibility across processes, we enable proactive management and real-time decision-making to address challenges as they arise. Leveraging advanced data analysis, we transform operational insights into actionable strategies, driving performance, reliability, and continuous improvement.

COLD CHAIN MANAGEMENT

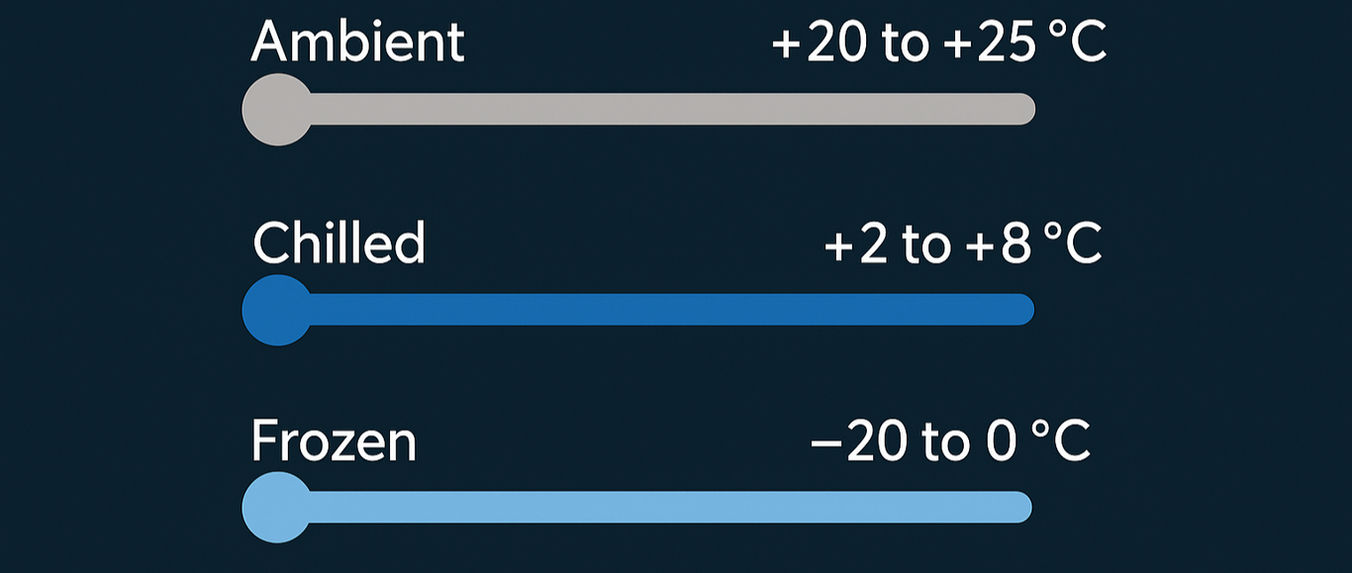

Temperature Profiles

Our warehousing solutions are designed to cater to a wide range of temperature requirements, ensuring product safety and quality. We maintain ambient storage conditions for general goods, while cool storage zones are carefully controlled between 15°C to 23°C to suit products that require a stable, moderate environment. For sensitive items, we offer cold storage facilities maintained between 2°C to 8°C, ideal for perishable goods and pharmaceuticals. Additionally, our negative temperature storage ranges from –20°C to 0°C, ensuring optimal preservation of frozen and highly temperature-sensitive products.

Temperature Visibility

All our cold chain operations are backed by complete temperature visibility to ensure product integrity at every stage. With real-time monitoring systems in place, we provide continuous oversight and instant alerts in case of deviations. Comprehensive traceability ensures full accountability across the supply chain, while detailed temperature and relative humidity (RH) mapping validates storage conditions. In addition, we maintain thorough reporting and documentation to support compliance, audits, and customer assurance.

Refrigerated Transport

We provide dedicated refrigerated transport solutions to ensure the safe movement of temperature-sensitive products. Our services include inter-warehouse transportation supported by a fleet of fully refrigerated vehicles equipped with live temperature monitoring systems for real-time visibility. To guarantee seamless operations, we also offer end-to-end logistics coordination, ensuring reliability and efficiency throughout the supply chain.

WareHouse Management

Rented Spaces

TWC is designed with the concept of Modern Warehousing, fully equipped to manage everything from basic to advanced storage requirements. Our facilities are tailored to accommodate high-density storage solutions as well as cost-efficient layouts, ensuring flexibility, efficiency, and reliability for diverse warehousing needs.

Top Class Facility Hygiene and Maintenance

At TWC, we provide a complete range of professional services to ensure hassle-free upkeep and uncompromised safety across our facilities. With 24-hour power back-up, operations continue smoothly without interruption, while advanced CCTV surveillance systems monitor the premises round the clock for maximum security. Our professional security team enforces strict access control and safeguards the warehouse environment, supported by regular housekeeping and maintenance that keep the facilities clean, hygienic, and well-maintained. Together, these services create a secure, efficient, and reliable space for your goods.

Specialized Services

TWC offers specialized services designed to meet the diverse needs of modern warehousing. Our facilities include temperature-controlled storage solutions to preserve sensitive products, advanced machine-handling equipment for efficient movement of goods, and customized racking systems that maximize space utilization while ensuring easy accessibility. In addition, we provide skilled manpower support to handle day-to-day operations with precision and reliability, creating a seamless and efficient warehousing experience for our clients.

Project Management

TWC provides comprehensive project management services, ranging from greenfield developments to the upgrading of existing facilities. Our expertise covers layout design and space optimization to ensure maximum efficiency, while our 3PL warehouse management solutions streamline logistics and operations. We also implement lean solutions to reduce waste and enhance productivity, supported by specialized warehouse consulting that helps clients design, operate, and scale their facilities effectively.

Specialized Packaging

State of the art machine equipments

TWC is equipped with state-of-the-art packaging technology sourced from renowned brands, ensuring precision and reliability in every process. Our facilities feature advanced inkjet coders for accurate product marking, high-performance pouch sealers for secure and consistent packaging, and efficient taping machines that guarantee durability and protection during transit. Together, these technologies enable us to deliver packaging solutions that are fast, reliable, and aligned with modern industry standards.

Lean Process

At TWC, we follow lean processes designed to maximize efficiency while upholding the highest standards of quality. Through careful workforce planning, we ensure that manpower is utilized effectively to meet operational needs. Our commitment to industry best practices enables us to maintain consistency and reliability across all activities, while integrated supply chain planning ensures smooth coordination from storage to distribution. Together, these practices create a streamlined, cost-effective, and performance-driven warehousing environment.

Compliances

TWC ensures fully compliant warehousing and packaging operations, adhering to the highest industry and regulatory standards. Our facilities are ISO, FSSAI, and FDA approved, reflecting our commitment to safety, hygiene, and quality at every stage. We maintain strict labour compliance practices to ensure ethical and efficient workforce management, while regular stability checks and equipment calibration guarantee accuracy and reliability in all processes. This strong compliance framework provides our clients with complete confidence and peace of mind.

Material Management

TWC offers complete material management solutions within a hygienic and well-maintained environment, ensuring that goods are handled with the utmost care. Our expertise spans inbound and outbound logistics, providing seamless movement of materials across the supply chain. With robust material management practices and regular stock audits, we maintain accuracy, transparency, and efficiency at every stage, giving clients the assurance of reliable and well-organized warehouse operations.

bottom of page